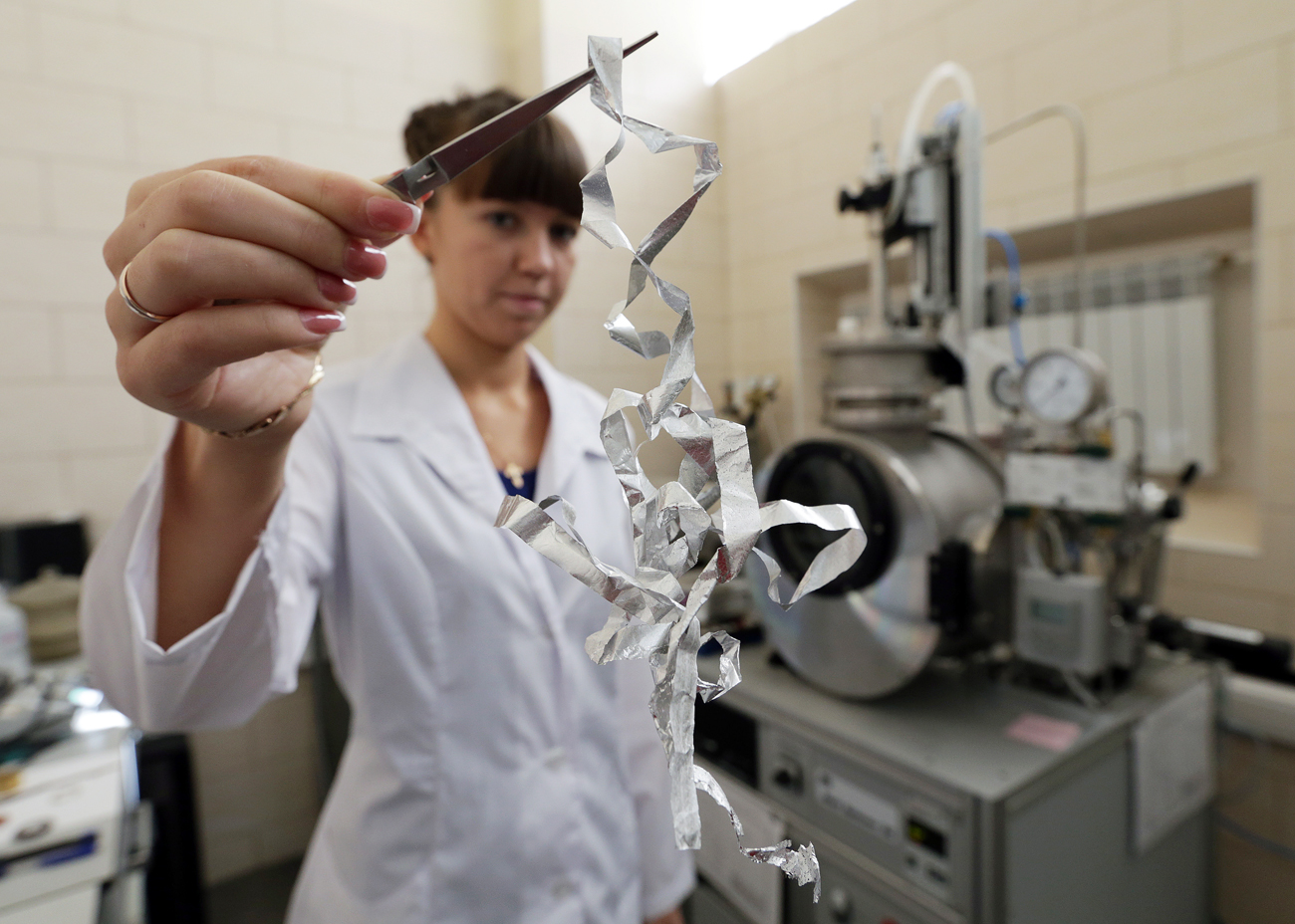

A lab worker at the research laboratory for non-organic nanotubes and graphene at the MISiS National University of Science and Technology.

Artyom Geodakyan/TASSScientists from the National University of Science and Technology (MISiS) have developed implants that mimic the structure of bone tissue, and which will help repair damaged flat bones such as blades, skull and pelvis, as well as filling in areas where bone tissue is missing due to injury or cancer.

The implants are made of ultra-high-molecular-weight polyethylene — a biocompatible material already widely used in medicine. The new implants consist of two layers. As in organic bone tissue, the implants have a solid layer that is the most durable and resistant to external influences. Blood vessels and tissue, however, can grow into the light porous layer that allows the implant to settle in the body quicker.

“Most existing implants are made either of ceramic or synthetic material, and consist of either only a porous layer or only a solid one,” said Fyodor Senatov, PhD in physical and mathematical sciences and one of the implant's developers. “Our implant's main advantage is that it's both porous and elastic, and thus resistant to cracking.”

Ultra-high-molecular-weight polyethylene is elastic, which allows the surgeon to modify and cut the bone implant during surgery. “This might be necessary if, for example, damage to the bone tissue was severe and cannot be clearly identified during an MRI or CT scan,” Senatov said. “So, instead of filing the bone down to adjust it to the implant, it is better to file the implant and preserve the bone as much as possible.”

In addition, the implant's outer solid layer is saturated with antibiotics to prevent infection after surgery. The inner porous layer is inoculated with the patient's bone marrow cells, which in turn speeds up the implant's fusion with body tissues.

“This breakthrough will lead to a dramatic reduction in the number of post-operative septic complications,” said Mikhail Kiselevsky, MD and one of the developers. “Thus, there will be a significant reduction in the cost of care for the patient during rehabilitation.”

The implant is already in preclinical studies, and was successfully used to heal a bone defect in laboratory mice and rats. Clinical trials will begin after the full cycle of preclinical tests is completed, and then will take about five years.

When the clinical trials are finished the state-owned pharmaceutical company GosZMP plans to produce a pilot batch of the implants for free distribution to veterinary clinics.

Meanwhile, scientists filed several patent applications in Russia, and will soon get an international patent. The implants will certainly be popular in Russia where demand is high — about 60,000 surgeries to replace flat bone defects are performed in the country each year.

All rights reserved by Rossiyskaya Gazeta.

Subscribe

to our newsletter!

Get the week's best stories straight to your inbox