Russia begins production of electric engines at EU premium standards

This is the only factory in Russia whose products meet premium EU standards for energy efficiency. Only the world’s leading manufacturers, such as Siemens, ABB and WEG, produce engines at these standards, the Industry Development Fund reported to RBTH.

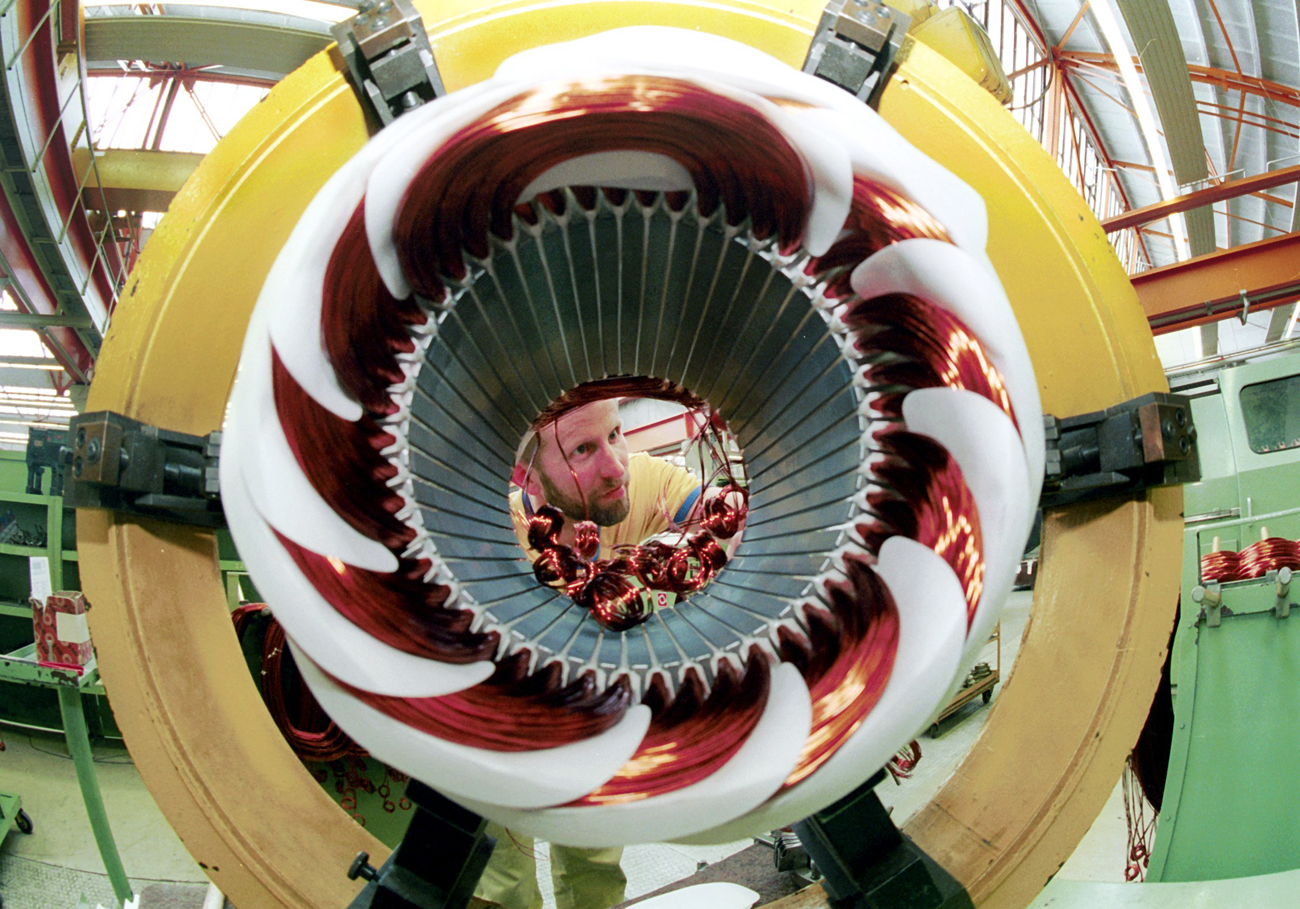

DPA/Vostock-PhotoOn Nov. 18, Genborg Company launched the production of electric motors to be used in mining, metallurgical, chemical and food industries. The factory is located in the Lipetsk Region, 310 miles southeast of Moscow.

According to Genborg, this is the only factory in Russia whose products meet premium EU standards for energy efficiency. Only the world’s leading manufacturers, such as Siemens, ABB and WEG, produce engines at these standards, the Industry Development Fund reported to RBTH.

“The factory was originally conceived for exports, which is why it was named Genborg, which sounds more European,” the plant's general director Fyodor Dudin said in an interview with RBTH. At full capacity, the factory is expected to supply 10% of the products sold in Western Europe, 30% in the CIS market, and 60% of products on the Russian market. Deliveries to countries near and far are expected to start in 2017, Dudin said.

Why they need a new factory

Genborg received production investments of 1.4 billion rubles ($21.5 million), half of which came from the largest bank in Russia, Sberbank, and the special government-created Industrial Development Fund. The factory can produce 25 thousand motors a year for 1.3 billion rubles ($20 million). By 2021, the company hopes to hold 8% of the Russian market.

Aleksei Shedrov, head of innovation and industrial policy of Lipetsk Region, told RBTH that other factories in the region are expected to use the engines, including NLMK, one of the largest Russian metallurgical companies; the machine-building corporation TSNO Khimmash; and the Italian company Indesit's local manufacturing plant.

Genborg also anticipates their engines will be used by the Intermash machine-building company in Lipetsk, which recently received a loan from the Industrial Development Fund, said Yuri Shamkov, Deputy Director of the Fund. Today, Intermash supplies machinery to the CIS, Europe, China and Southeast Asia.

Production with VEM Company

German IE-2 and IE-3 engines will also be used in the metallurgical industry. However, according to Rüdiger Strümpel, Managing Director of VEM Motors, Genborg and VEM products will not compete but instead will "complement one another," because VEM will produce engines for different uses.

“Today VEM produces approximately 2,500 different types of electrical engines and supplies them for all industries and purposes around the world, from power plants to shipbuilding,” said Strümpel. They are also planning to release engines under the brand name of Genborg, using VEM parts, Strümpel elaborated.

An additional line with a capacity of 5,000 – 10,000 units per year will be installed at the Lipetsk plant in order to manufacture VEM Motors products. The terms of their cooperation are still being discussed; it may be a partial contract for manufacturing and partial for production under Genborg’s name, said Fyodor Dudin, director of the plant.

At the plant’s opening, Genborg also signed an agreement to supply components from the German company Schuler, which specializes in processing metals with pressure and volume pressing, technologies necessary for producing engines.

Read more: Car engineer Pablo Iturralde: Constructing the future>>>

Subscribe to get the hand picked best stories every week

All rights reserved by Rossiyskaya Gazeta.

Subscribe

to our newsletter!

Get the week's best stories straight to your inbox